Turn signals, seemingly simple components, are crucial for safe driving. They communicate our intentions to other drivers, preventing accidents and ensuring smooth traffic flow. However, these vital systems are often exposed to the elements, making them susceptible to moisture intrusion. Water damage can lead to a variety of problems, from erratic blinking and bulb failures to complete system failure. Understanding how water enters the turn signal system and how a professional auto repair shop tackles these issues is essential for maintaining vehicle safety and preventing costly repairs.

Pinpointing the Source: Tracking Down the Leak

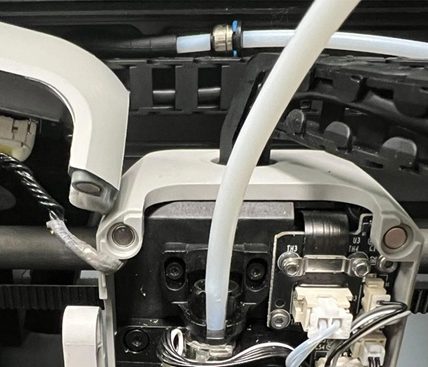

The first step in addressing moisture-related turn signal problems is identifying the source of the water. Common entry points include cracked or damaged lens housings, worn-out gaskets and seals around bulb sockets, and compromised wiring harnesses. A skilled technician will visually inspect the turn signal assemblies for any signs of physical damage. They might also use a water hose to carefully simulate rain conditions, observing where water infiltrates the system. Sometimes, a more subtle approach is required, involving the use of specialized dyes added to the water to trace its path. Proper diagnosis is paramount, as simply replacing a bulb without addressing the underlying leak will only result in a recurring problem. Choosing the Auto Repair in Sardinia, OH based service is essential.

Cleaning and Drying: Restoring Proper Function

Once the source of the leak is identified and addressed (e.g., by replacing a cracked lens or a deteriorated gasket), the focus shifts to cleaning and drying the affected areas. Water can cause corrosion on electrical contacts and wiring, leading to poor connections and erratic behavior. Technicians often use electrical contact cleaners to remove corrosion and restore conductivity. Compressed air is used to thoroughly dry the components, ensuring no residual moisture remains. In some cases, particularly with heavily corroded terminals, replacement of the affected wiring or connectors may be necessary to guarantee a reliable connection.

Beyond the Bulb: Addressing Wiring and Control Modules

While a faulty bulb is often the initial suspect in a turn signal malfunction, moisture can also damage the wiring harness and even the vehicle’s body control module (BCM), which manages various electrical functions, including turn signals. Technicians will carefully inspect the wiring for signs of corrosion, fraying, or damage. They may use a multimeter to test the continuity and voltage of the wiring circuits, ensuring proper signal transmission. If the BCM is suspected of being damaged, further diagnostic testing is required, and in some cases, the module may need to be reprogrammed or replaced.

Prevention and Maintenance: Keeping Water at Bay

Preventing moisture intrusion is always preferable to dealing with the aftermath. Regular visual inspections of turn signal assemblies can help identify potential problems before they escalate. Replacing cracked or damaged lenses promptly is crucial. Applying dielectric grease to bulb sockets can help protect against corrosion and improve electrical connections. For vehicles frequently exposed to harsh weather conditions, consider applying a sealant around the edges of the turn signal housings to create an extra barrier against water intrusion. By taking a proactive approach, vehicle owners can minimize the risk of water-related turn signal problems and ensure their vehicle’s safety systems remain in optimal condition.