With increasing demands for performance, emission control, and reliability, material innovation plays a crucial role in the development of advanced automotive components.

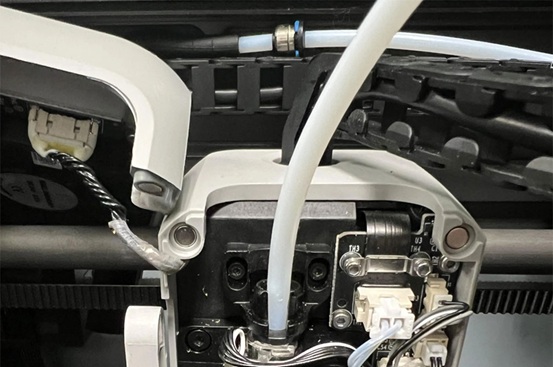

One such innovation is the use of PTFE tubing in automotive fuel systems. Thanks to its unique chemical and physical properties, PTFE (Polytetrafluoroethylene) tubing has emerged as an indispensable material in fuel delivery lines, vapor recovery systems, and other critical fuel system components.

Challenges in Automotive Fuel Systems

Automotive fuel systems must safely transport fuel from the tank to the engine while preventing leaks, contamination, and vapor loss. Key challenges include:

- Chemical compatibility: Fuels today often contain additives, ethanol blends, or biofuels that can degrade conventional tubing materials.

- Temperature extremes: Fuel lines are exposed to hot engine compartments and cold weather conditions.

- Pressure fluctuations: Fuel pumps and injectors generate varying pressures that tubing must endure without failure.

- Environmental regulations: Strict emission standards require the containment of fuel vapors to reduce pollution.

- Durability: Components must last for thousands of miles without cracking, leaking, or deteriorating.

Addressing these challenges requires materials that combine chemical resistance, mechanical strength, and flexibility.

How PTFE Tubing Enhances Fuel Systems

1. Superior Chemical Resistance

PTFE is virtually inert to most chemicals, including hydrocarbons, ethanol, methanol, and other aggressive fuel additives. Unlike rubber or FEP tubing that can swell, crack, or degrade, PTFE tubing remains stable, preventing fuel contamination and ensuring consistent flow characteristics throughout the vehicle’s lifespan.

2. High Temperature Tolerance

Operating temperatures in automotive fuel systems can range from sub-zero environments to well over 200°C near engine components. PTFE tubing can withstand temperatures from approximately -70°C to +260°C without losing its mechanical integrity or becoming brittle, making it ideal for use close to the engine or exhaust system where heat resistance is critical.

3. Low Permeability and Vapor Barrier

PTFE tubing provides excellent resistance to fuel vapor permeation, helping automotive manufacturers meet stringent environmental standards by reducing evaporative emissions. This containment helps protect the environment and improves overall vehicle efficiency.

4. Flexibility and Lightweight

The flexible nature of PTFE tubing allows easier routing within the tight and complex spaces of modern vehicles. Its lightweight profile also contributes to reducing overall vehicle weight, which is beneficial for fuel economy and emissions.

5. Durability and Longevity

PTFE’s resistance to cracking, abrasion, and aging means fuel system components last longer, reducing maintenance costs and improving vehicle reliability. PTFE tubing maintains its integrity even under repeated vibration and pressure cycles common in automotive environments.

6. Non-Flammable and Safe

PTFE’s high melting point and non-flammable nature add a layer of safety by reducing fire hazards associated with fuel systems, especially in case of leaks or accidents.

Typical Applications of PTFE Tubing in Automotive Fuel Systems

- Fuel Lines: From the tank to the engine, PTFE tubing safely transports gasoline or diesel fuel.

- Vapor Recovery Systems: Prevents vapor loss and reduces emissions in fuel tanks and charcoal canisters.

- Fuel Injector Lines: High-pressure fuel delivery lines benefit from PTFE’s chemical resistance and durability.

- Fuel Filter Connections: Ensures clean fuel delivery by providing stable connections that resist degradation.

Industry Trends and Future Outlook

With the automotive industry moving towards hybrid and alternative fuel vehicles, the chemical composition of fuels is diversifying. PTFE tubing’s versatility makes it well-positioned to adapt to future fuels such as bioethanol, hydrogen blends, and synthetic fuels.

Moreover, advances in PTFE composites and multilayer tubing are further enhancing performance by improving abrasion resistance and mechanical strength, while maintaining chemical inertness.

Conclusion

PTFE tubing plays a vital role in enhancing automotive fuel systems by offering superior chemical resistance, high temperature tolerance, durability, and environmental compliance. Its application improves fuel delivery efficiency, reduces maintenance costs, and supports the automotive industry’s move towards cleaner, safer, and more efficient vehicles. As material science progresses and fuel technologies evolve, PTFE tubing is set to remain a cornerstone component in the design of advanced automotive fuel systems.